Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

Polysiloxane with weather-resistant and toughening suitable for cationic UV curing ChangFu® BEX12T.

Changfu Chemicals newly launches high-purity double-ended reactive silicone product ChangFu® BEX12T 1,5-Bis[2-(3,4-epoxycyclohexyl)ethyl]-1,1,3,3,5,5-hexamethyltrisiloxane; CAS No.: 150856-78-3). This advanced silicone-based epoxy monomer features excellent flexibility, outstanding weather resistance, and low surface tension, enabling superior wetting, leveling, and compatibility with various organic resins and inorganic fillers. Its unique alicyclic epoxy structure delivers higher reactivity and faster curing speed under cationic photo-initiation conditions, significantly outperforming traditional glycidyl ether-type epoxy monomers in curing efficiency, thermal stability, and yellowing resistance.

ChangFu® BEX12T is widely applicable to high-end cationic UV-curing coatings, electronic encapsulation and potting materials, optical adhesives and coatings, high-performance composite matrices, and 3D-printing UV-curable resins. It effectively improves the flexibility, toughness, adhesion, weatherability, and thermal/chemical resistance of cured systems, helping customers achieve more stable production processes, higher product performance, and longer service life in demanding industrial applications.

Product features:

- Excellent weather resistance:

The unique molecular structure of ChangFu® BEX12T, which synergistically combines the stable siloxane backbone with highly UV-resistant alicyclic epoxy groups, endows the cured coating with exceptional anti-ultraviolet aging and anti-yellowing properties. Unlike conventional epoxy systems prone to degradation under long-term UV exposure, this product maintains superior gloss retention, color stability, and mechanical integrity even in harsh outdoor environments, significantly extending the service life of coatings and materials.

- Optimized rheological and surface properties:

Featuring low surface tension and excellent flowability, ChangFu® BEX12T acts as an efficient leveling agent, effectively eliminating surface defects such as orange peel, pinholes, and brush marks, thereby enhancing the smoothness, gloss, and overall appearance of the coating. In addition, its inherent silicone characteristics impart excellent hydrophobicity and anti-fouling properties to the cured film, reducing surface adhesion of dust, water, and contaminants, and facilitating easy cleaning and maintenance.

- High reactivity and curing speed:

Benefiting from the high ring strain and unique structural characteristics of alicyclic epoxy groups, ChangFu® BEX12T exhibits extremely high reactivity in cationic polymerization systems. It enables rapid UV curing even at low light intensity or short exposure time, significantly improving production efficiency. The fast-curing kinetics also ensure high crosslinking density and complete conversion, resulting in coatings with outstanding hardness, adhesion, and chemical resistance, making it ideal for high-speed automated coating lines and high-performance applications

Application:

- Special coating field:

Fast curing coating: Suitable for high-efficiency production scenarios such as industrial coating lines and roll-to-roll processes. Its low viscosity ensures excellent leveling, wetting, and high-gloss finish, enabling high-speed coating and rapid UV curing, thereby improving production throughput and surface quality.

High-performance protective coating: Exhibits outstanding heat resistance, chemical resistance, solvent resistance, and electrical insulation after UV curing. It is widely used in PCB solder mask inks, electronic component temporary/ permanent protective coatings, conformal coatings for circuit boards, and insulating coatings for electronic devices, providing long-term reliability in harsh environments.

- 3D printing UV-curable resin:

As a key functional component in cationic UV-curable 3D printing resins, it effectively reduces curing shrinkage and internal stress, significantly improving dimensional accuracy, stability, and mechanical toughness of printed parts. It helps prevent warpage, deformation, cracking, and layer delamination, making it suitable for high-precision prototyping, structural parts, and functional components in UV-curable 3D printing systems.

- Toughener and stress reliever:

When incorporated into epoxy-based cationic UV systems, its flexible siloxane segments disperse stress generated during UV curing, enhance coating flexibility, impact resistance, and adhesion, and reduce brittleness. It effectively prevents cracking, peeling, or chipping on rigid substrates such as metal, glass, ceramic, and composite materials, extending service life and improving durability under thermal cycling or mechanical impact.

- Adhesion promoter & modifier for UV-curable systems:

Improves adhesion between UV-curable coatings/inks and difficult substrates (e.g., plastics, glass, metals, inorganic fillers). It also enhances compatibility between organic resins and inorganic fillers, improving dispersion, reducing viscosity, and boosting mechanical properties, weatherability, and abrasion resistance of the cured film.

- Other UV-curable applications:

Can be used in UV-curable inks, varnishes, encapsulants, and potting compounds for electronics, optical devices, and automotive coatings, providing improved flexibility, weathering resistance, and long-term stability under UV exposure and environmental stress. ChangFu® BEX12T is a reactive silicone additive designed for high-performance cationic UV curing systems.

It perfectly combines the excellent flexibility and long-term weather resistance of silicone with the fast UV curing speed and high thermal stability of alicyclic epoxy resins. This unique molecular design effectively addresses the common drawbacks of traditional UV-curable materials, such as high brittleness, poor adhesion to difficult substrates, and insufficient weathering resistance, making it an ideal choice for high-performance UV-curable formulations in coatings, 3D printing resins, adhesives, and electronic encapsulation applications.

Note: For more product information, please contact our technical team to obtain detailed product materials and professional technical support.

Contact Information:

Phone: (+86) 181-6277-0058

Email: sales@cfsilanes.com

Our technical support team is ready to provide professional product selection advice, customized method development support, and targeted application problem-solving assistance. With deep expertise in material science, formulation design, and composite processing, we work closely with you to optimize material selection, streamline production processes, resolve technical bottlenecks, and enhance end-product performance.

Key words: Reactive siloxane; CAS: 150856-78-3; 1,5-Bis[2-(3,4-epoxycyclohexyl) ethyl]-1,1,3,3,5,5-hexamethyltrisiloxane; Cationic UV curing.

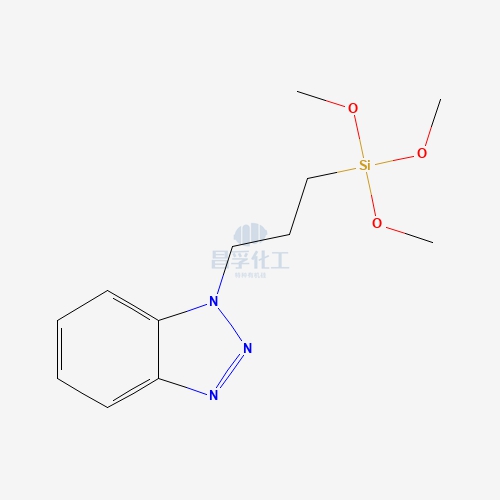

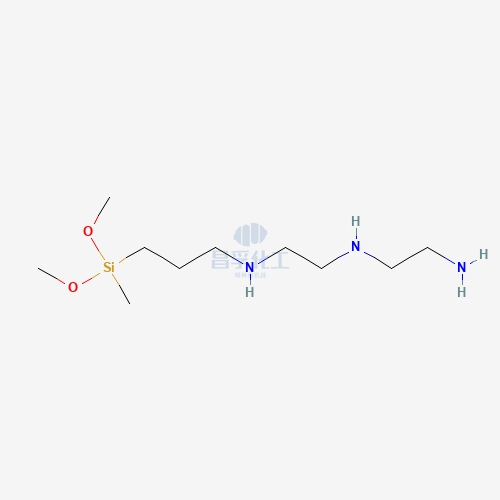

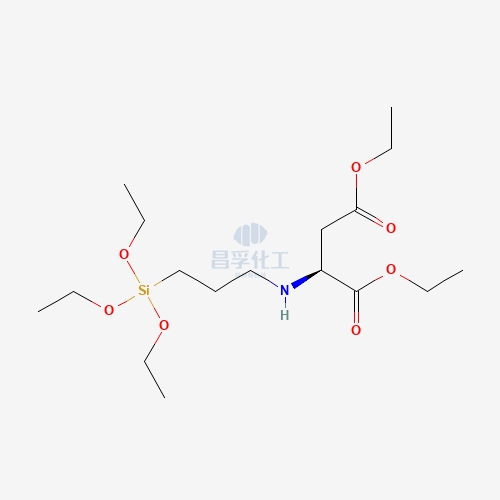

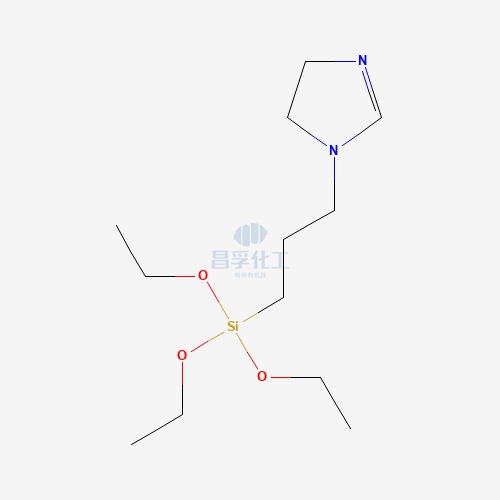

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog