Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

Low-Viscosity Hydrophobic Siloxane for Enhanced Thermal Interface Materials & Filler Treatment ChangFu® VM12H

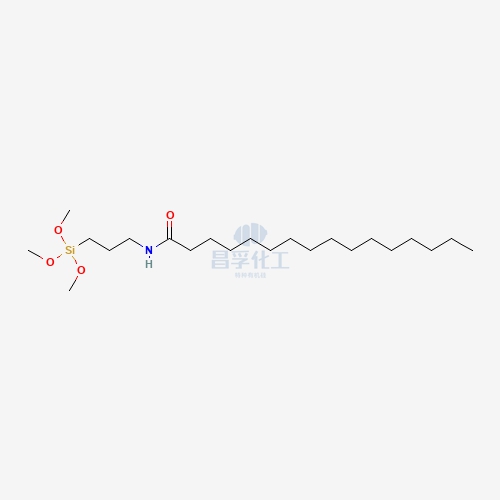

Hubei Changfu Chemical has launched a high-quality hydrogen-containing siloxane core additive — ChangFu® VM12H (chemical name: 1,1,3,3-tetramethyl-1-[2-(trimethoxysilyl)ethyl]disiloxane, CAS No.: 137407-65-9). Relying on precise molecular structure design, this product boasts three core advantages: excellent interfacial adhesion, stable chemical structure, and good processing compatibility. In application, it can effectively reduce the thermal resistance of thermal interfaces, significantly improve the structural reliability and usage stability of material systems. With its outstanding performance, it has become a key supporting additive in the research, development and production of high-end and high-performance thermal interface materials and thermal packaging materials, providing core technical support for the performance upgrading of related materials.

- Product Features:

1. High hydrophobicity

The molecular structure carries flexible hydrophobic tetramethyldisiloxane segments, which can form strong covalent bonds with the surface of hydrophilic inorganic materials, efficiently modify the surface properties, transform it into a long-term stable hydrophobic surface, significantly improve the water resistance and moisture-proof performance of the material, and the hydrophobic effect is long-lasting and not easy to diminish.

2. Excellent viscosity reduction and dispersibility

It is suitable for various high-filled inorganic filler composite systems, can quickly penetrate into the gap between filler particles, effectively reduce the overall viscosity of the system, and improve the processing rheological properties; at the same time, with the help of spatial steric hindrance effect, it strongly inhibits the agglomeration and sedimentation of filler particles, and realises the uniform dispersion of filler in the system, ensuring the consistency and long-term stability of product performance.

3. The interface strengthening effect is outstanding

It has both reactive groups matched with inorganic fillers and siloxane segments compatible with organic polymers, which can form a strong chemical bond and tight molecular bond at the interface between inorganic fillers and organic polymers, greatly improve the interface adhesion, effectively solve the problem of poor compatibility between the two-phase interface, significantly enhance the tensile, bending, impact and other mechanical properties of composite materials, and improve the overall structural strength and durability of materials.

- Application fields:

1. High-performance composite materials——coatings, inks and adhesives

Hydrophobic/self-cleaning coatings: As a key modification additive, they endow coatings with long-lasting and stable hydrophobic/superhydrophobic properties, significantly improving their self-cleaning, anti-pollution and anti-icing capabilities. They are suitable for exterior building walls, automotive coatings, solar panel protection and the surfaces of special industrial equipment.

Pigment and filler treatment: By performing surface treatment on inorganic pigments (such as titanium dioxide, iron oxide, etc.) and functional fillers, their dispersion stability and compatibility in resin systems are greatly improved, thereby enhancing the coloring power, gloss, hiding power and printability of coatings or inks, as well as reducing system viscosity and improving production efficiency.

Adhesive and sealant enhancement: Applied in systems such as silicone sealants and epoxy adhesives, they effectively optimize the dispersion and bonding of fillers, not only improving the process performance of products such as extrudability and construction fluidity, but also simultaneously enhancing the mechanical strength, weather resistance and interface bonding reliability of the final cured products.

2. High-performance thermal conductive and packaging materials

Thermal interface materials (TIMs): Used in thermal conductive gels, thermal conductive potting compounds and thermal conductive gaskets, etc., they significantly reduce system viscosity, improve fluidity, and ensure full wetting and coating of complex microstructured electronic components. After curing, an efficient heat dissipation path with a uniform thermal conductive network and low internal stress is formed, ensuring the long-term stable operation of electronic devices.

High thermal conductive insulating composite materials: By performing surface treatment on flake or spherical high thermal conductive insulating fillers such as boron nitride (BN) and aluminum oxide, their oriented arrangement and interface compatibility in polymer matrices (such as silicone resin, epoxy resin) are improved. Composite films or molding compounds with excellent insulation, high thermal conductivity and good flexibility can be prepared, which are widely used in heat dissipation management of high-power density integrated circuits (ICs), light-emitting diodes (LEDs) and power devices.

Highly filled packaging systems: In systems such as epoxy molding compounds (EMC) and silicone packaging materials, as processing aids and interface modifiers, they allow a higher proportion of functional fillers (such as silica, aluminum oxide, etc.) to be filled. While significantly improving the thermal conductivity of materials, they effectively control the coefficient of thermal expansion (CTE) of the system, reduce curing shrinkage and interface stress, and improve the mechanical reliability and service life of packaged devices.

3. Reinforcement and modification of silicone rubber and silicone resin

Reinforcing filler treatment: Specifically used to treat key reinforcing fillers such as fumed silica. By improving their affinity with the silicone rubber matrix (raw rubber), they effectively inhibit filler agglomeration and the "structuring" phenomenon of silicone rubber, improve mixing uniformity and storage stability, and ultimately significantly optimize the key properties of vulcanized rubber such as tensile strength, tear strength and transparency.

Performance improvement of liquid silicone rubber (LSR): Added to LSR formulations, it can enhance the mechanical properties (such as tear resistance, wear resistance) and thermal stability of cured products while maintaining excellent injection fluidity and operating process window, meeting the growing demand for high-performance silicone rubber products in automotive, medical, baby products and other fields.

Endowment of special bonding properties: Used in self-adhesive silicone rubber formulations, through modifying interface effects, it significantly enhances the bonding strength and durability between silicone rubber and various difficult-to-bond substrates (such as metals, engineering plastics, glass), expanding the application of silicone rubber in fields such as composite structural parts, sealing assemblies and flexible electronics.

For more information about products and applications, please contact us:

Mobile: (+86) 181-6277-0058

Email: sales@cfsilanes.com

Key words:CAS: 137407-65-9; 1,1,3,3-tetramethyl-1-[2-(trimethoxysilyl)ethyl]disiloxane; Hydrogen-containing siloxane; Hydrophobic.

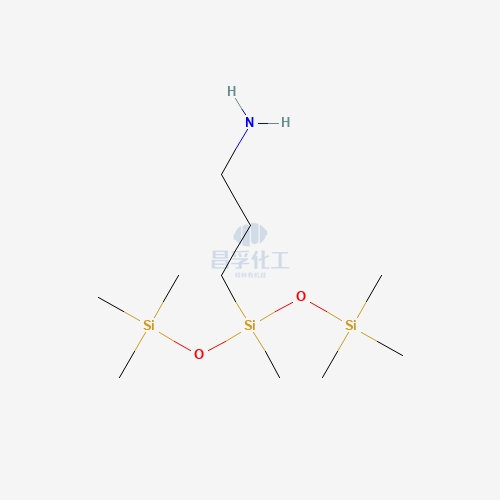

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog