Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

High-Purity Adhesion Promoter Adaptable to Diverse Application Scenarios ChangFu® TRN33.

In the fields of composite materials, high-performance coatings, and precision electronic packaging, interface failure has long been recognized as the critical bottleneck restricting product durability, stability, and upper performance limits. Under harsh service conditions—including high humidity, thermal cycling, mechanical stress, and chemical corrosion—weak interfacial bonding often leads to delamination, cracking, peeling, or performance degradation, directly shortening product lifespan and undermining long-term reliability. Traditional physical adsorption or conventional coupling treatments rely primarily on weak intermolecular forces or insufficient chemical bonding, which can no longer satisfy the increasingly stringent requirements of modern industrial applications.

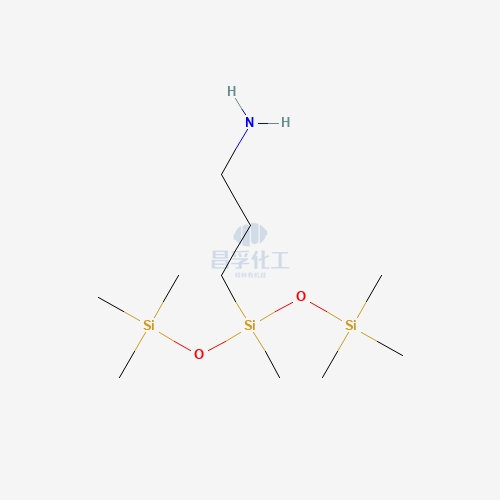

To overcome these challenges and achieve stable, long-lasting interfacial adhesion, ChangFu Chemical has developed and launched a high-purity, professional-grade adhesion promoter: ChangFu® TRN33 (Tris[3-(triethoxysilyl)propyl]amine, CAS: 18784-74-2). Built on advanced molecular design principles, this specialty silane coupling agent forms strong, stable covalent bonds between inorganic substrates and organic polymers, effectively enhancing interfacial compatibility, bonding strength, and environmental resistance. By addressing interfacial weaknesses at the molecular level, ChangFu® TRN33 provides a systematic, high-reliability solution for advanced manufacturing in composites, high-performance coatings, and precision electronic packaging.

Product Features:

- High Purity Guaranty

Adopting advanced purification technology and strict quality control system, ChangFu® TRN33 achieves ultra-high purity with extremely low impurity content. This ensures stable and consistent product performance in every batch, effectively eliminates common defects such as paint pinholes, fisheyes, uneven curing, and local foaming of adhesives caused by impurities. It greatly reduces production anomalies, improves product yield and appearance quality, and makes the manufacturing process more stable, smooth and efficient.

- Excellent Water Resistance & Durability

During application, ChangFu® TRN33 can hydrolyze and condense to form a dense, cross-linked siloxane protective layer with outstanding hydrophobicity. This structure effectively blocks moisture, water vapor and corrosive media from penetrating into the material interface, significantly improving resistance to harsh environments including damp-heat aging, salt spray corrosion, water soaking and weathering. It maintains long-term interface stability and greatly extends the service life of finished products.

- Enhanced Substrate Adhesion & Corrosion Resistance

As a multi-functional amino silane coupling agent, ChangFu® TRN33 acts as a molecular bridge between inorganic substrates (metal, glass, filler, etc.) and organic polymers (resin, coating, adhesive, etc.). It significantly improves interfacial adhesion, peel strength and bonding fastness, while enhancing the overall corrosion resistance of the material system. Stronger adhesion and better protection effectively reduce interface failure, peeling and rusting risks, greatly improving reliability and durability under severe working conditions.

Application fields:

1. High-performance Coatings & Adhesives

- Industrial Anti-Corrosion Coatings

As a core adhesion promoter, ChangFu® TRN33 forms a stable covalent bond bridge between the coating film and metal substrates (including carbon steel, stainless steel, aluminum alloys, and galvanized steel). This effectively prevents coating peeling, blistering, and rust penetration, extending the service life of anti-corrosion systems in harsh marine, industrial, and outdoor environments.

- Adhesives & Sealants

Serving as a functional additive for epoxy resin adhesives, polyurethane sealants, and silicone sealants, ChangFu® TRN33 is suitable for bonding and sealing scenarios involving multiple substrates. It not only improves the bonding strength and shear strength of the system but also enhances weather resistance, high-low temperature resistance and moisture resistance. It is widely used in architectural curtain wall bonding, automotive component sealing, electronic device assembly, and civil engineering bonding, ensuring long-term stability of bonding and sealing effects even in extreme temperature changes and humid environments.

2. Special Surface Treatment

- Glass Surface Treatment

Applicable to the surface treatment of various glass products, including automotive glass, architectural glass, electronic display glass, and optical glass. For glass surfaces that require subsequent coating, spraying, or bonding (such as automotive glass coating, display glass touch layer bonding), it can build a high-adhesion active interface, solving the problem of poor bonding between traditional glass surfaces and organic coatings/adhesives, and improving the durability and service life of glass products.

- Metal Pretreatment

Ideal for pretreatment processes of metal workpieces before phosphating, passivation, or coating, and can also be used as a standalone surface treatment layer for precision metal components. During treatment, ChangFu® TRN33 forms a thin, uniform, and corrosion-resistant silane film on the metal surface, which can effectively remove residual oxides and impurities on the metal surface, improve the uniformity and adhesion of subsequent phosphating/passivation films.

3. Electronic Packaging & Materials

A key functional additive in electronic packaging materials, especially suitable for epoxy molding compounds (EMC) used in chip packaging, as well as packaging of diodes, transistors, and integrated circuits. ChangFu® TRN33 can significantly improve the bonding reliability between epoxy molding compounds and chip surfaces or lead frames. It effectively reduces the interfacial stress caused by differences in thermal expansion coefficients between different materials, thereby reducing the risk of packaging delamination, cracking, and leakage in high-temperature, humid, and hot environments. This ensures the long-term stability and reliability of electronic components, meeting the high requirements of automotive electronics, consumer electronics, and industrial electronics for packaging performance.

Note: Specific applications should be evaluated based on actual conditions.

For further product details and application support, please contact us.

Mobile phone:(+86)181-6277-0058

Email:sales@cfsilanes.com

Key words: Tris[3-(triethoxysilyl)propyl]amine; CAS:18784-74-2; Adhesion promoter; Coating; Surface treatment.

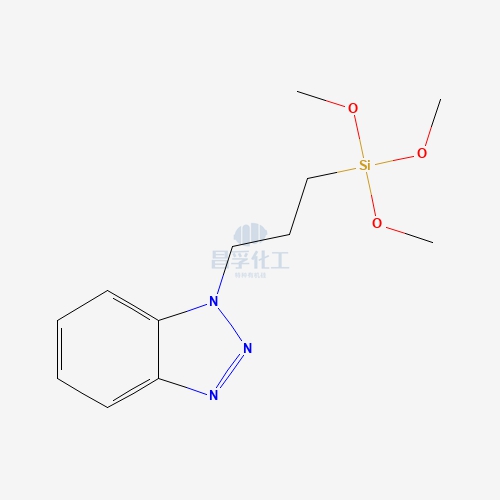

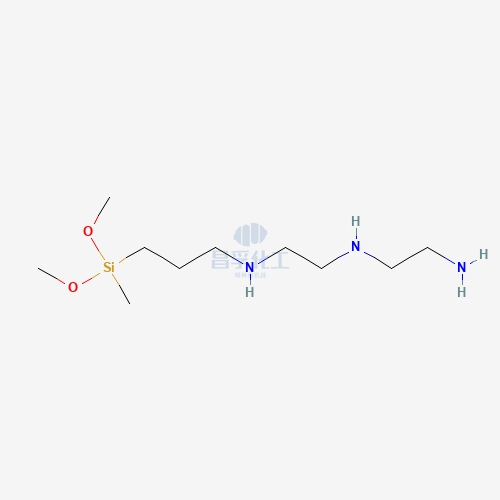

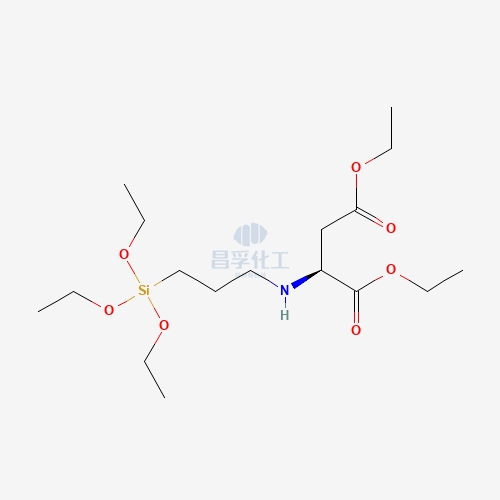

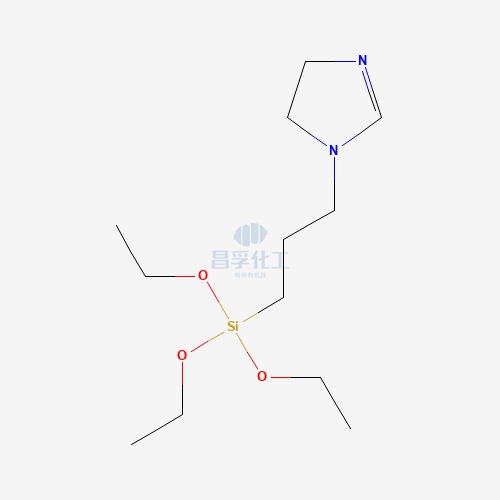

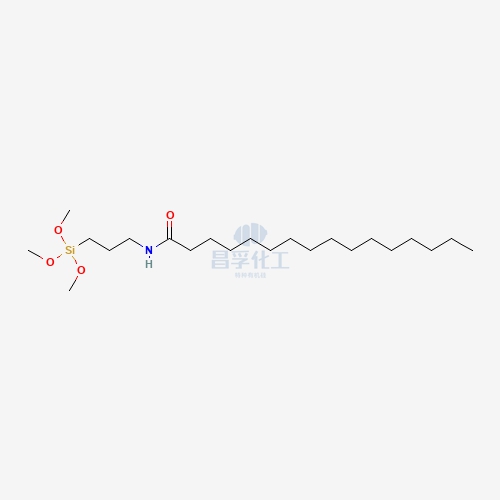

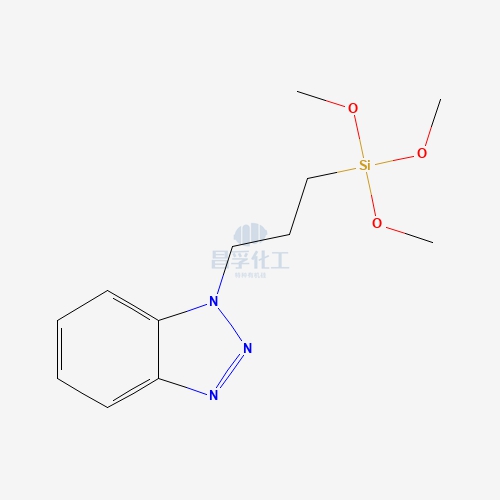

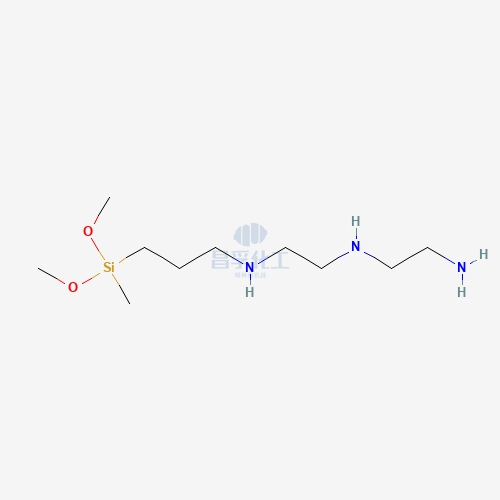

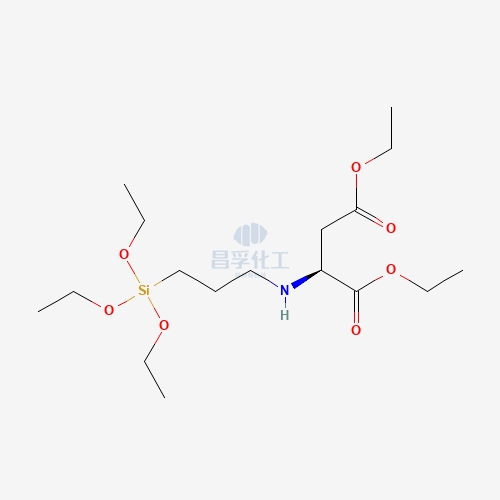

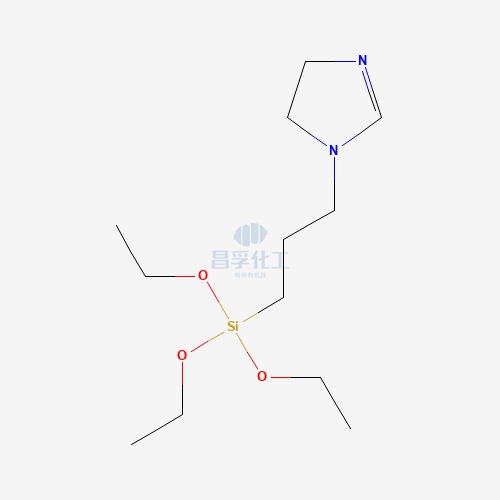

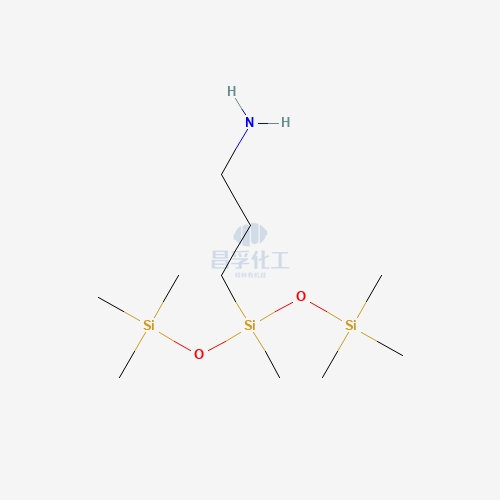

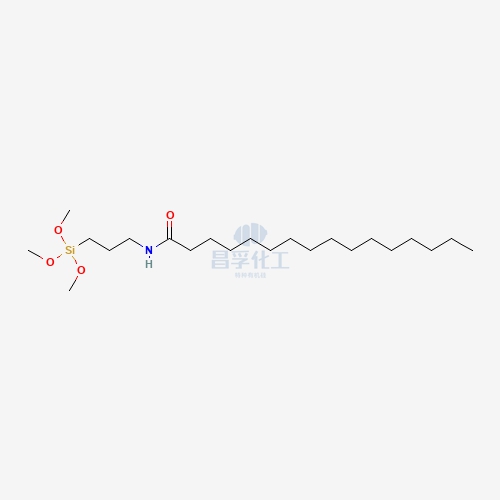

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog

+86 27 8439 6550

+86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

+86 27 8439 6550 | +86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

Copyright © Hubei ChangFu Chemical Co., Ltd. All Rights