Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

ChangFu® VM12H – Low-Viscosity Hydrophobic Siloxane for Enhanced Thermal Interface Materials & Filler Treatment.

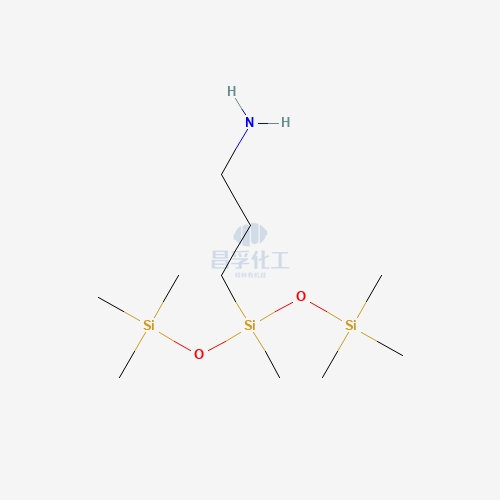

ChangFu® VM12H {1,1,3,3-tetramethyl-1-[2-(trimethoxysilyl)ethyl]disiloxane; CAS: 137407-65-9} is a hydrogen-containing siloxane developed by ChangFu Chemical. It delivers strong interfacial adhesion, excellent structural stability, and improved processability—effectively reducing interfacial thermal resistance while enhancing system reliability. As a result, it has become a key additive in the formulation of high-performance thermal interface materials (TIMs) and thermally conductive packaging solutions.

Key Features:

n High Hydrophobicity – Its flexible tetramethyl disiloxane segments convert hydrophilic inorganic surfaces into durably hydrophobic ones.

n Excellent Viscosity Reduction & Dispersion – Significantly lowers viscosity in highly filled systems and prevents particle agglomeration through steric hindrance for long-term dispersion stability.

n Superior Interfacial Reinforcement – Builds a stable bond between inorganic fillers and organic polymers, noticeably improving the mechanical properties of composites.

Applications:

1. High-Performance Composites – Coatings, Inks & Adhesives

l Hydrophobic/Self-Cleaning Coatings – Imparts lasting water resistance and anti-fouling properties.

l Inorganic Pigment Treatment – Enhances dispersion stability, color strength, gloss, and printability.

l Silicone Sealants – Optimizes filler performance, improves strength, and enhances extrusion processability.

2. High-Performance Thermal Interface & Encapsulation Materials

l Thermal Gel/Potting Compounds – Improves flow for complex potting applications; ensures uniform thermal conductivity and low stress after curing.

l Thermally Conductive Insulating Films – Treats flake-type high-thermal-conductivity fillers (e.g., boron nitride) to produce flexible, insulating, and thermally conductive films for high-power device cooling.

l Epoxy & Silicone Encapsulants – Reduces system viscosity, increases filler loading and thermal conductivity, and helps control the coefficient of thermal expansion (CTE).

3. Silicone Rubber & Resin Modification

l Fumed Silica Treatment – Improves dispersion in raw rubber, reduces structuring, and significantly boosts the strength and transparency of vulcanized rubber.

l Liquid Silicone Rubber (LSR) – Maintains processing fluidity while enhancing the mechanical properties of finished parts.

l Self-Adhesive Silicone Rubber – Strengthens adhesion to metals, plastics, and other substrates.

For more product and application details, please contact:

Phone: (+86) 181-6277-0058

Email: sales@cfsilanes.com

Key words:CAS: 137407-65-9; 1,1,3,3-tetramethyl-1-[2-(trimethoxysilyl)ethyl]disiloxane; Hydrophobic.

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog

+86 27 8439 6550

+86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

+86 27 8439 6550 | +86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

Copyright © Hubei ChangFu Chemical Co., Ltd. All Rights