Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

Changfu Chemical TA32: The Ideal Solution for UV Curing — Delivering “High Reactivity, Strong Adhesion & Enhanced Performance”

In UV curing applications, achieving high reactivity, strong adhesion, and enhanced performance is a common objective. Yet, challenges such as weak interfacial bonding and insufficient crosslinking often hinder progress. ChangFu® TA32 (Tri-acrylatesilane) is an innovative product specifically formulated to overcome these issues.

Mechanism of Action:

The TA32 molecule features multiple unsaturated double bonds. Under UV light or in the presence of thermal initiators, it rapidly undergoes free radical copolymerization with substrates containing double bonds, such as acrylate resins. Within seconds to tens of seconds, a highly crosslinked three-dimensional network is formed. This process ensures high polymerization conversion and minimal residual monomers, fully meeting the rapid-curing demands of UV processes.

Product Features:

- Three-Dimensional Interfacial Crosslinking

Builds a dense crosslinked network on inorganic surfaces, endowing composites with exceptional rigidity and dimensional stability. Particularly suitable for high-performance nanocomposites and structural adhesives.

- High-Functionality Reactivity

With multiple acrylate groups that actively participate in the photopolymerization reaction, TA32 acts as a key crosslinking point. This enhances surface hardness and resistance in UV-cured coatings and 3D printing resins.

- Dense Network Reinforcement

Constructs a robust interfacial barrier that significantly improves chemical and moisture resistance. This enhances damp-heat aging performance and long-term reliability in electronic packaging materials.

- Strong Anchoring and Stiffening Effect

Leveraging both chemical bonding and physical crosslinking, TA32 delivers exceptional interfacial adhesion in highly filled engineering plastics, along with notable reinforcement and stiffening effects.

Application Areas:

- UV-Curable Coatings/Inks

Functions as both a crosslinking agent and an adhesion promoter. Its multi-double-bond structure increases crosslink density, improving hardness and wearresistance—while the silane terminals form strong chemical bonds with substrates such as metal and glass, resolving issues of poor adhesion and peeling.

- UV-Curable Sealants

In electronic device encapsulation, the polyacrylate silane structure enables rapid crosslinking and curing. Simultaneously, the silane terminals bondeffectively with ceramic/metal casings, enhancing sealing performance and stability under damp-heat conditions.

Today, ChangFu® TA32 has become an indispensable component in the field of UV-curable materials. Changfu Chemical remains committed to empowering industrial innovation with advanced technologies, helping customers overcome a wide range of process challenges.

For more product and application information, please contact:

Mobile: (+86) 181-6277-0058

Email: sales@cfsilanes.com

Key words: Tri-acrylatesilane; UV curing; Interfacial Crosslinking; UV-Curable Coatings/Inks; UV-Curable Sealants.

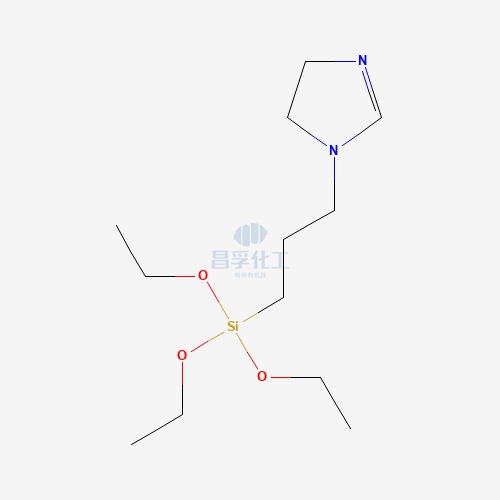

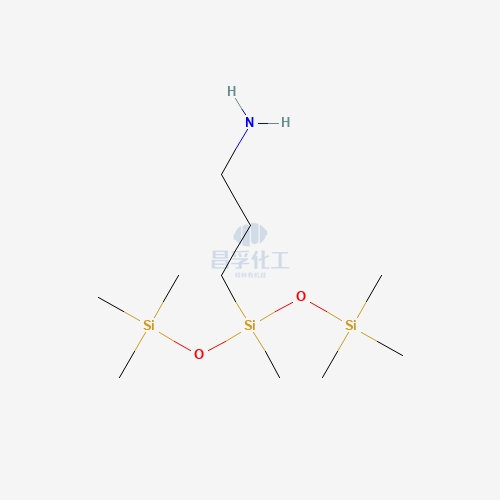

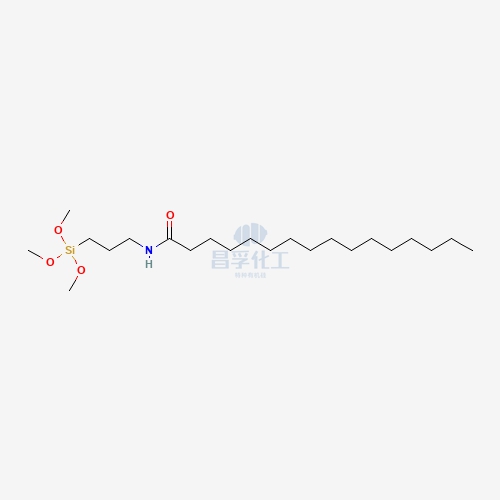

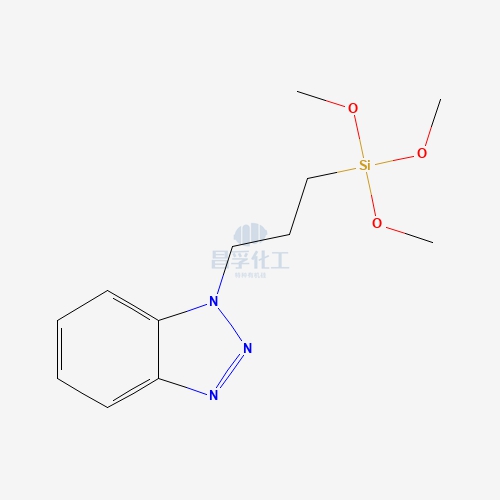

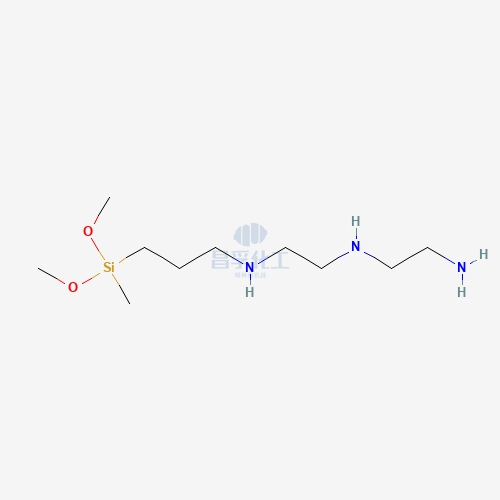

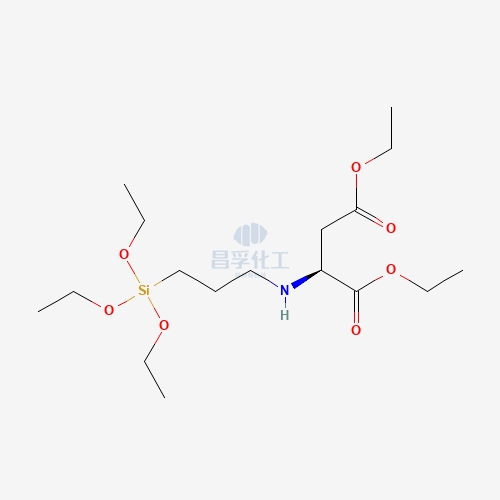

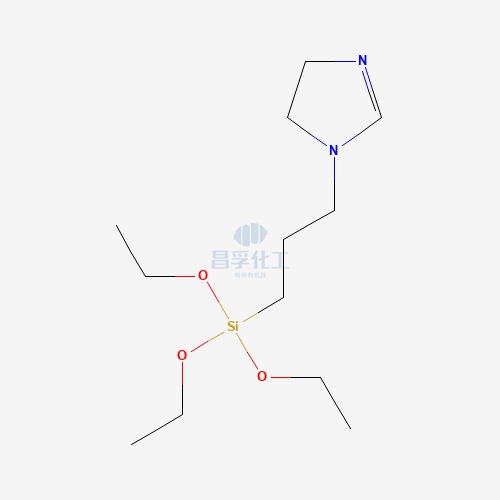

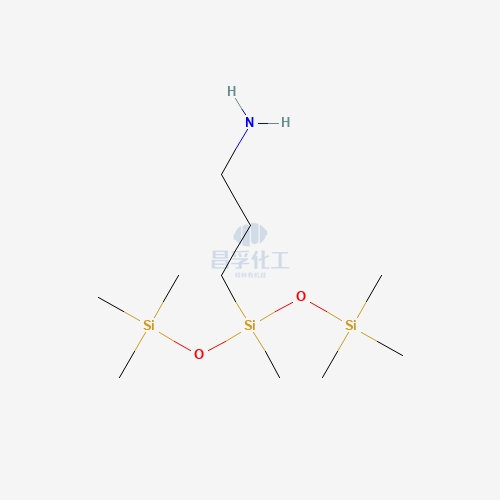

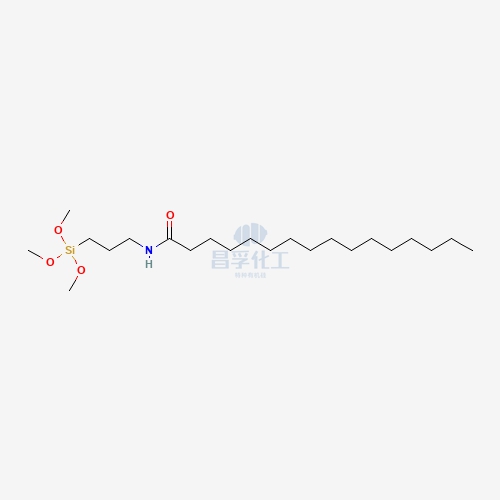

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog

+86 27 8439 6550

+86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

+86 27 8439 6550 | +86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

Copyright © Hubei ChangFu Chemical Co., Ltd. All Rights