Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

Carboxy-Functional Silane Coupling Agent:An Efficient Additive for Filler Dispersion, Interfacial Enhancement, and Metal Anti-Corrosion ChangFu® LNA33.

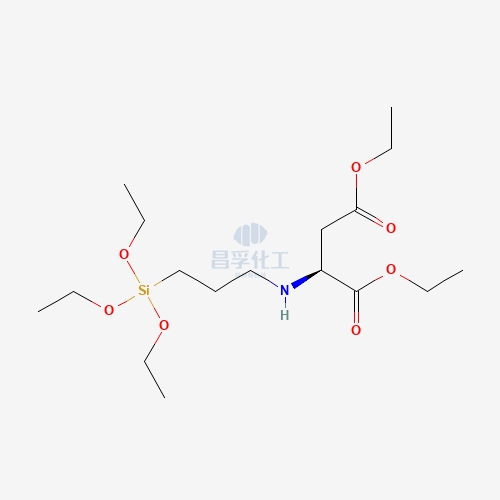

ChangFu® LNA33 {Triethoxysilylpropylmaleamic acid; CAS: 33525-68-7} is a silane coupling agent that integrates strong anchoring capability with highly reactive carboxyl functional groups. The silane end forms covalent bonds with inorganic surfaces through controllable hydrolysis, while the carboxyl end can react with organic functional groups such as epoxy and amino groups, thereby building a robust organic-inorganic interface. This product is increasingly becoming an indispensable key additive in demanding fields requiring superior adhesion, hydrolysis resistance, and corrosion protection—such as metal treatment, biological immobilization, and high-performance composites—significantly enhancing the mechanical properties and weather resistance of end products.

1. Core Advantages:

- Outstanding Interfacial Modification

Acts as a powerful molecular bridge, significantly enhancing the interfacial compatibility between organic resins and inorganic fillers. By reducing phase boundary defects and stress concentrations, it effectively boosts the composite material's tensile strength, impact toughness, and hydrolysis resistance, thereby ensuring stable performance and extending service life in harsh environments.

- Excellent Compatibility and Dispersion

The unique carboxyl functional group endows the product with superior polarity and reactivity. This promotes excellent wetting and uniform dispersion of inorganic fillers (e.g., silica, calcium carbonate, talc) in polymer matrices, effectively preventing filler agglomeration. This not only improves processing stability and surface smoothness but also ensures the consistency and reliability of the final product's performance.

- Metal Anti-Corrosion and Adhesion Enhancement

In metal protective coatings and adhesive applications, it forms robust chemical bonds with both the metal substrate and the organic coating, drastically improving adhesion. Furthermore, its weak acidic nature facilitates the formation of a dense, protective passivation film on metal surfaces, which effectively inhibits electrochemical and chemical corrosion. This makes it an ideal choice for applications requiring long-term durability in highly corrosive environments.

- Enhanced Weatherability and Durability

By strengthening the interface and reducing internal defects, it significantly improves the material's resistance to UV radiation, temperature fluctuations, and moisture penetration. This effectively mitigates issues such as cracking, chalking, and delamination, ensuring the material maintains its mechanical properties and aesthetic appearance over an extended service life.

- Broad Compatibility and Versatility

Exhibits excellent compatibility with a wide range of polymers (e.g., polyolefins, polyesters, acrylics, epoxies) and inorganic substrates (fillers, metals, glass). This versatility allows for its effective use across diverse applications, including coatings, adhesives, sealants, and polymer composites, providing a universal solution for performance enhancement.

2. Key Application Scenarios

- Reinforcement of High-Performance Composites:

Copolymerization & Adhesion Boost:

Reacts and copolymerizes with unsaturated resins (e.g., styrene, acrylics, vinyl esters), forming a stable chemical network that drastically enhances interlayer adhesion and structural integrity. This is critical for advanced composites used in aerospace, automotive lightweighting, and wind turbine blades, where high strength-to-weight ratios and fatigue resistance are essential.

Filler/Fiber Surface Treatment:

Used for surface modification of mineral fillers (talc, calcium carbonate, silica, mica) and glass/carbon fibers. It significantly improves interfacial bonding with polymer matrices, boosting composite tensile strength, flexural modulus, impact resistance, and dimensional stability while optimizing processing flowability. This enables the production of high-performance plastic compounds, engineered wood composites, and fiber-reinforced polymers (FRPs) for structural and semi-structural applications.

Silica-Reinforced Rubber Systems:

Acts as an effective coupling agent between silica fillers and rubber matrices (e.g., natural rubber, styrene-butadiene rubber). It reduces compound viscosity for easier processing, improves wet skid resistance, and lowers rolling resistance—ideal for high-performance tire treads, industrial rubber goods, seals, and hoses. By enhancing filler-rubber interaction, it also improves abrasion resistance and service life under dynamic stress.

- High-Reliability Coatings and Structural Bonding

Anti-Corrosion Coatings for Harsh Environments:

Serves as a critical adhesion promoter and corrosion inhibitor in metal anti-corrosion coatings. It forms robust bonds with both metal substrates (steel, aluminum, galvanized metals) and organic resins (epoxies, polyurethanes, acrylics), delivering long-term protection against salt spray, chemicals, humidity, and atmospheric corrosion. This makes it indispensable for marine coatings, industrial maintenance coatings, automotive primers, and infrastructure protection systems.

Structural Adhesives Enhancement:

Added to epoxy, polyurethane, and acrylic structural adhesives to significantly improve peel strength, shear strength, and durability. It ensures reliable bonding under high loads, thermal cycling, humid conditions, and chemical exposure, meeting stringent performance requirements in aerospace, automotive assembly, construction, and electronics manufacturing. Its ability to bridge dissimilar substrates (metal-plastic, metal-composite) expands design flexibility and enables lightweight, high-strength bonding solutions.

- Specialty Functional Material Design

Antibacterial & Active Packaging Materials:

Compatible with reactive oxygen species (ROS) generation systems and antimicrobial agents. It aids in developing bio-based and food packaging materials with synergistic antibacterial functions, extending shelf life, reducing microbial contamination, and ensuring food safety. Its surface modification capabilities also enhance barrier properties and printability, making it suitable for high-performance packaging applications.

Surface Functionalization & Sensing:

Used to construct self-assembled monolayers (SAMs) on metal, glass, or oxide surfaces. Enables precise control of surface wettability (hydrophilic/hydrophobic balance), provides effective corrosion protection, and serves as a functional platform for biosensors, microelectronics, and lab-on-a-chip devices. Its reactive carboxyl groups facilitate the immobilization of biomolecules, enzymes, or nanoparticles, enabling advanced sensing, diagnostic, and microfabrication applications.

Note: For more product information, please contact our technical team to obtain detailed product materials and professional technical support.

Contact Information:

Phone: (+86) 181-6277-0058

Email: sales@cfsilanes.com

Key words: Silane coupling agent; Triethoxysilylpropylmaleamic acid; CAS: 33525-68-7; Carboxyl functional group; Anti-Corrosion; Adhesion promotion.

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog