Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

A Newly Upgraded Coupling Agent – Flexible Interface Solution for High-Stress Scenarios ChangFu® EPO32.

In applications subjected to high mechanical stress, severe structural deformation, or extreme thermal cycling conditions, rigid inorganic-organic interfaces are prone to microcracking and interfacial debonding, which have long been a critical weak point plaguing material performance and reliability, and directly hindering the R&D innovation and upgrade iteration of high-end products. To address this industry pain point, ChangFu Chemical has independently developed and launched the high-performance modified silane coupling agent ChangFu® EPO32. This innovative product ingeniously incorporates ether-bond flexible segments into its molecular backbone; while fully retaining the robust dual-directional bonding capability of traditional silane coupling agents—enabling firm covalent bonding with inorganic substrates (e.g., glass, metal, mineral fillers) on one end and effective compatibility with organic resins on the other—it endows the interface with exceptional flexibility, excellent deformation adaptability and efficient stress-buffering performance.

Product Features:

- Excellent Chemical Resistance:

The flexible and robust interface constructed by the product maintains structural integrity even under prolonged exposure to corrosive chemical media, effectively resisting the infiltration and erosion of acids, alkalis, organic solvents and other harmful substances. This structural stability directly translates to enhanced chemical resistance and service life of the finished coatings, composites and adhesive products in harsh industrial environments.

- Enhanced Flexibility:

The precisely designed ether-bond flexible segments between inorganic substrates and organic resins. This unique molecular structure can efficiently alleviate the internal stress generated by the mismatch of thermal expansion coefficients between different materials during temperature cycles and fundamentally reduce the brittleness of the interface. It thus enables the material system to maintain excellent structural toughness against repeated deformation and temperature changes.

- Superior Adhesion Promotion:

The product features an optimized molecular design with more efficient and flexible crosslinking capabilities, which can form a dense and three-dimensional cross-linked network at the interface. This network achieves deeper, firmer and more durable bonding strength between substrates and organic phases, effectively preventing interfacial debonding, peeling and delamination. It further elevates the overall bonding performance and mechanical stability of the material system under dynamic or static stress conditions.

- Outstanding Compatibility and Stress Dissipation:

The extended ether-bond flexible chain segments with tailored molecular weight significantly improve the product’s compatibility and diffusion performance in various complex resin systems, especially in high-viscosity, low-polarity or multi-component blended resin systems that are traditionally difficult to modify. It can achieve uniform and full coating on the surface of various fillers, fibers and inorganic substrates, realizing ideal interface modification effects. Meanwhile, the flexible chain structure can dissipate the local concentrated stress in the material system through molecular chain torsion and extension, avoiding stress-induced microcracks and optimizing the overall mechanical properties of the material.

Applicable Fields:

- High-Performance Fiber-Reinforced Composites:

Effectively resists the damage of environmental factors such as humidity, temperature change and chemical corrosion to the fiber-resin interface, extending the long-term service life of finished products in complex and harsh working conditions.

Especially suitable for the manufacturing of high-end structural components in aerospace, automotive racing, high-speed rail, new energy equipment and high-performance mechanical equipment fields, which demand ultra-high structural strength while requiring excellent interlayer toughness, dynamic impact resistance and dimensional stability.

- Extreme Environment Coatings and Protective Coatings:

Improves the chemical resistance, weather resistance and corrosion resistance of the coating system, enabling the coating to maintain a complete and stable structure under the long-term action of acid, alkali, salt spray, organic solvent, ultraviolet radiation and extreme temperature cycles.

Widely applicable to anti-corrosion coatings for industrial equipment, marine engineering protective coatings, high-temperature resistant coatings for power equipment, anti-cracking coatings for civil engineering structures and special functional coatings for new energy battery shells, meeting the stringent protection requirements of various extreme working environments.

- High-Performance Elastic Adhesives:

Optimizes the interface bonding between adhesive and bonded substrates, significantly improving the shear strength, tensile strength and peel strength of the adhesive joint, and realizing the efficient stress transfer between different substrates. Endows the adhesive joint with excellent flexibility and deformation adaptability, effectively buffering the internal stress generated by the mismatch of thermal expansion coefficient and external mechanical load of different substrates, avoiding the brittle fracture of the adhesive joint and improving the overall structural reliability.

Suitable for structural bonding in aerospace, automotive manufacturing, shipbuilding, construction engineering and electronic equipment assembly, especially for the bonding of large components and precision components that require high bonding strength, good durability and strong environmental adaptability.

By effectively dissipating interfacial internal stress caused by thermal expansion and contraction or mechanical strain, ChangFu® EPO32 significantly improves the adhesion strength, peel resistance, and environmental durability of materials. It is an ideal functional additive for high-performance coatings, structural adhesives, advanced composite materials and other fields with stringent performance and stability requirements.

Note: Specific application effects should be evaluated based on actual conditions. Contact our technical team for more product information and professional support.

Contact:

Phone: (+86) 181-6277-0058

Email: sales@cfsilanes.com

Key words: Chemical Resistance; Adhesion Promotion; Flexibility; Silane coupling agent; ChangFu® EPO32.

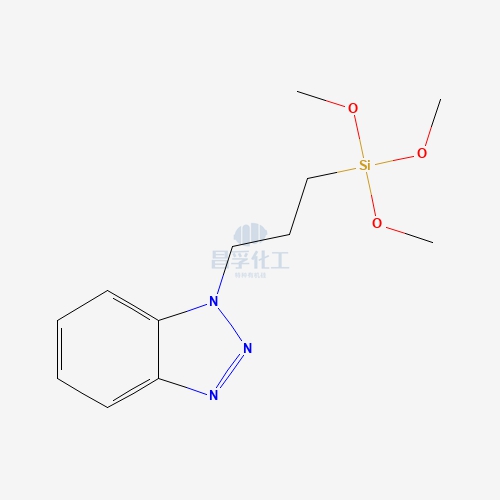

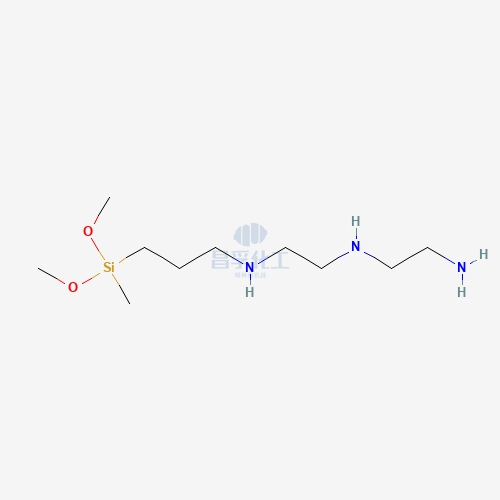

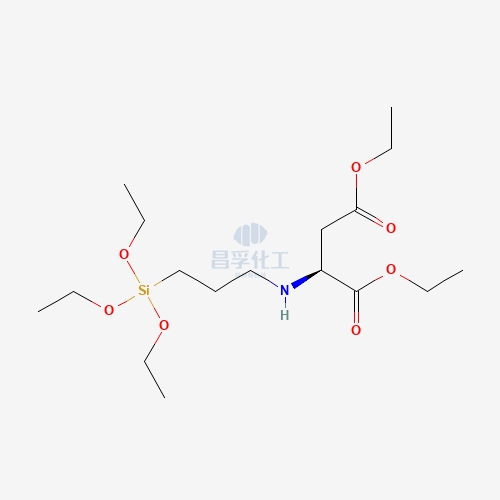

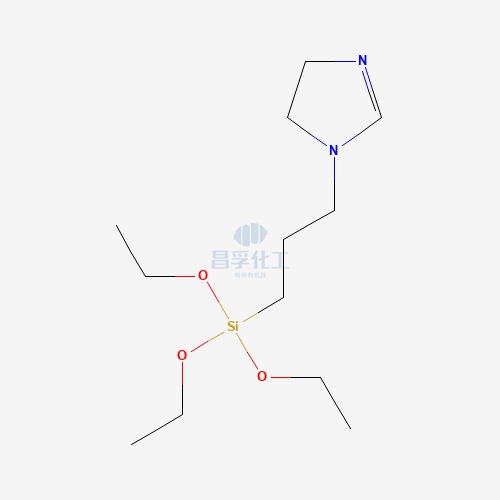

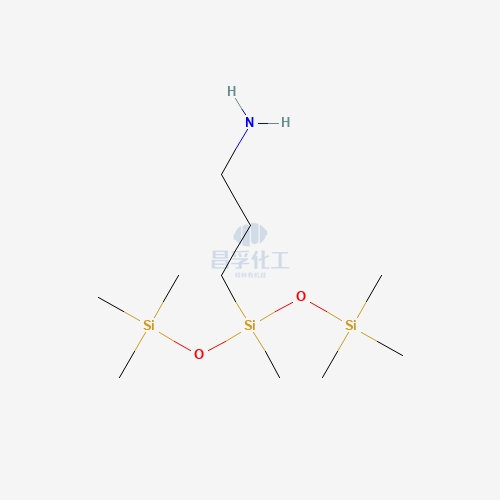

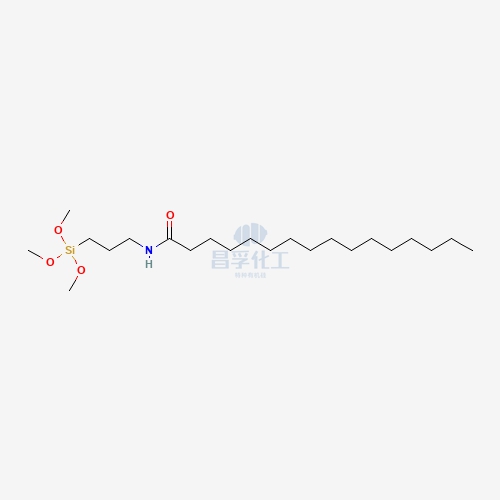

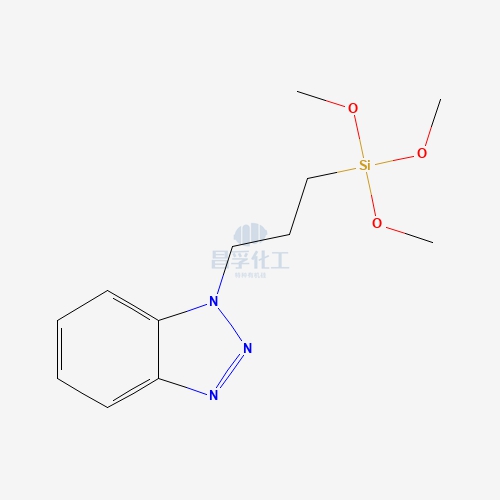

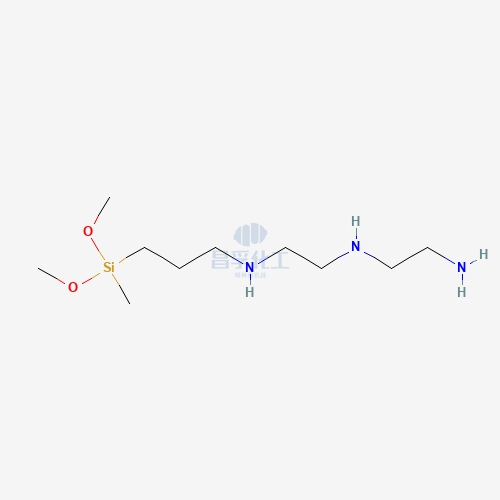

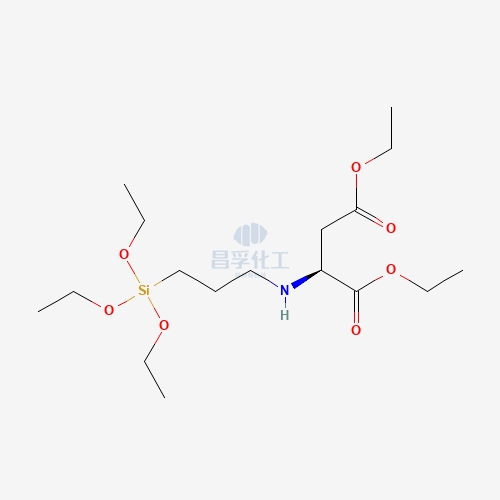

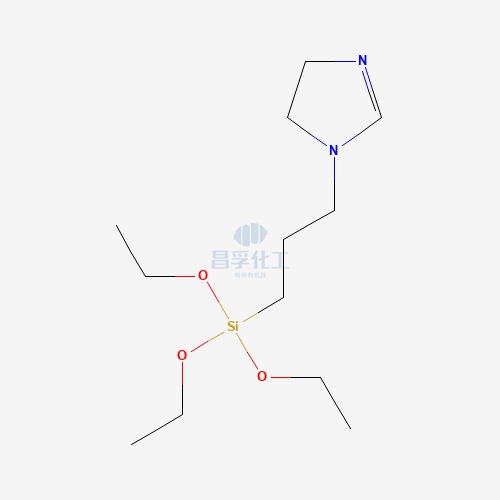

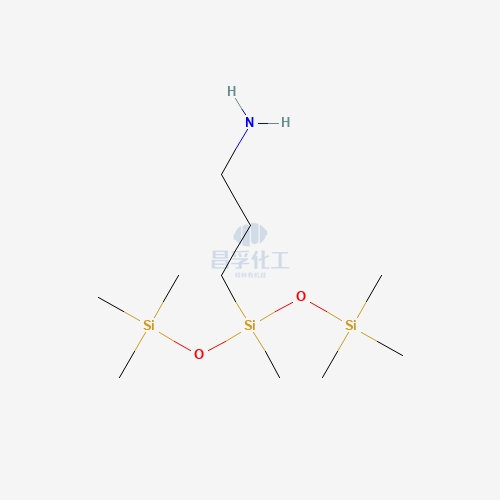

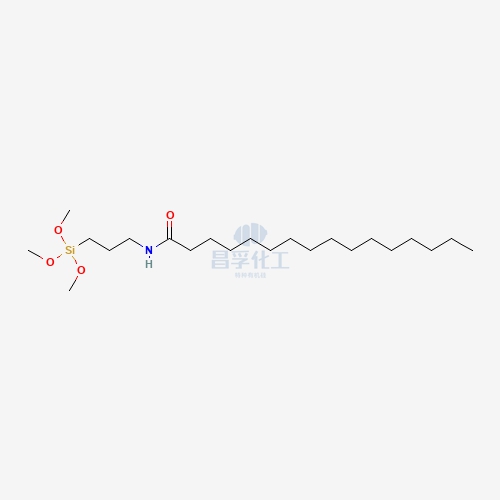

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog

+86 27 8439 6550

+86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

+86 27 8439 6550 | +86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

Copyright © Hubei ChangFu Chemical Co., Ltd. All Rights